An argument I hear regularly is that burning wood is a terrible way to provide heat, both for the environment and public health. This claim is supported by evidence drawn from wood stoves and open fires, and I agree, those are generally bad ways to heat things. But those aren’t the only options.

The reality is that burning biomass is the only truly sustainable and regenerative form of on-demand heating. The problem is that the current supply chain and the most widespread combustion technologies are both bad. It’s not that burning wood is bad, it’s that we’re doing it all wrong.

Here’s how to do it right.

Rocket Mass Heaters

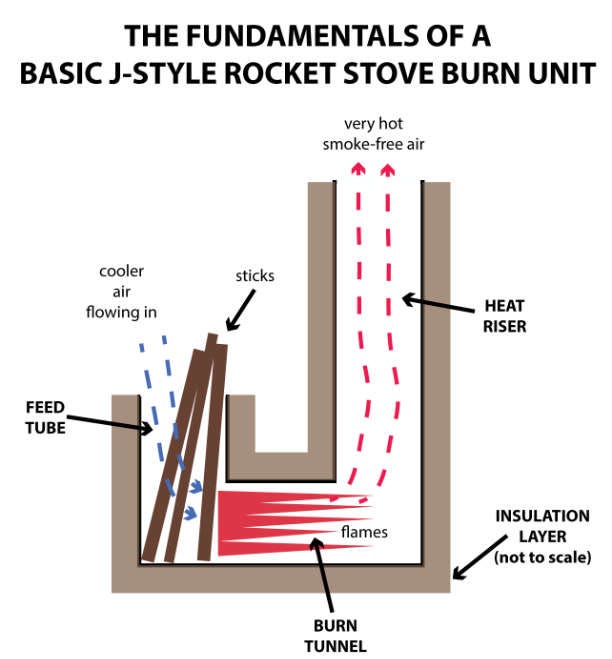

A rocket mass heater combines a rocket stove with a large quantity of thermal mass. A rocket stove is a J-shaped combustion chamber in which small diameter wood is burned at very high temperatures and achieves near complete combustion. This is made possible by the high airflow of the inlet and the high heat of the burn tunnel, which combusts much of the particulate generated by the fire. The very hot exhaust is smokeless and clean relative to a typical wood fire (this hot exhaust can then be used to heat a pan, oven, griddle, water heater, kiln, and a variety of other things.)

A rocket mass heater takes this already efficient process one step further. It adds a second combustion chamber where a convection current burns the remaining particulate and volatile gasses. This extracts more heat from the fuel source while simultaneously eliminating most of the pollution created by combustion.

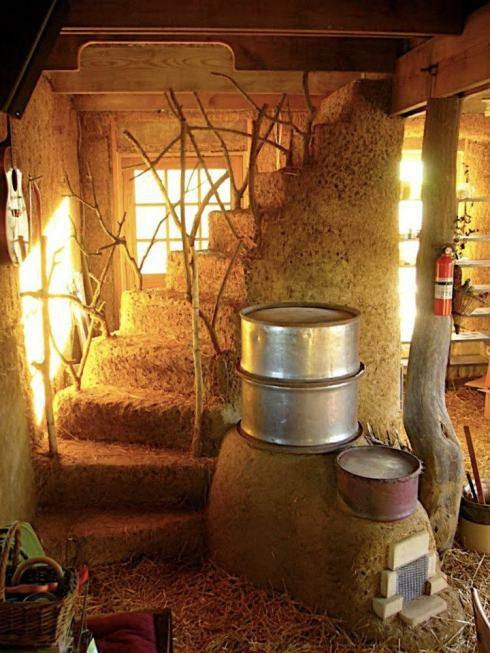

This process occurs within a big hunk of thermal mass—usually in the form of cob or rock—similar to a masonry stove. This thermal mass captures and stores nearly all of the heat created by the combustion, and then slowly releases it into the surrounding space. This slow release of heat plus highly efficient combustion mean that rocket mass heaters in homes typically only burn for an hour or two a day even on extremely cold days. In milder winters, people often only light them every other day. Think of it more as charging a thermal battery rather than heating with flames.

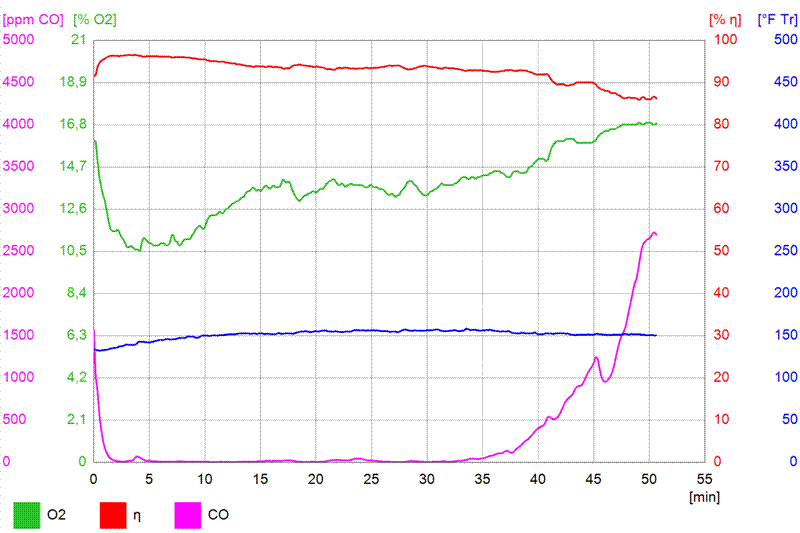

Wood stoves do not have any of these advantages, and so they typically burn all day everyday, while spewing smokey, hot exhaust into the outside air. That’s both wildly inefficient and unhealthy. The exhaust on a well-built rocket mass heater is cool enough that you can place your hand directly inside the exhaust outlet; all the heat has been trapped in the thermal mass.

Here’s what’s in the exhaust itself. It’s mostly steam, CO2, and a small amount of methane at start up and cool down (there is also a small amount of ash leftover, which has myriad uses):

The high airflow through a rocket mass heater has another big advantage: indoor air quality. Since air is constantly being pulled into the inlet and pushed out of the exhaust—the “roar” created by this effect is why they’re called “rocket” stoves—emissions from the fire are unable to create indoor air pollution, a major problem with wood stoves. In fact, a rocket mass heater doesn’t even need fire to draw air through the inlet, and this makes it a very effective passive cooling device as well.

All told, rocket mass heaters use 80-90% less wood than a wood stove while offering far superior performance. But there’s still the issue of their fuel source and CO2 emissions. That’s where the supply chain comes in.

Fuel production

It’s counterintuitive to most people, but producing fuel for rocket mass heaters can easily be carbon negative. In fact, it has enormous potential to be part of the solution to climate change.

But first, let’s talk briefly about the current wood supply chain: deforestation and tree plantations. Both of these are disastrous ecologically for obvious reasons. They decimate biodiversity, account for massive emissions, and require lots of fossil fuels for production and transportation. Scaling this up is a terrible idea, but that’s exactly what we’re doing. Even with the enormous efficiency improvements offered by rocket mass heaters, fueling them via the existing supply chain would only lessen the harm, not reverse it.

The biomass industry argues that since trees regrow, cutting them down for wood stoves or pellet mills is a carbon-neutral form of production. There are two main problems with this: 1) It takes decades for full-size trees to regrow, and the CO2 released by their combustion heats the planet in the meantime, 2) The entire supply chain is powered by fossil fuels, so you have to count those inputs, too.

So what we need is something that: 1) Regrows quickly, 2) Can thrive without inputs on currently deforested/degraded land, and 3) Can be grown and harvested close to its end user.

Coppice agroforestry checks all of those boxes. Fortunately, the indispensable Lowtech Magazine has already written a great piece on regenerative coppice agroforestry, and you can read it here.

A couple of things I would add, though. Coppice agroforestry is carbon negative because only the aboveground wood is harvested. But trees store 26% of their carbon in their roots, and a significant amount of carbon is deposited on the ground as leaf litter, which then becomes soil organic matter. Assuming those represent an increase in organic matter from the previous use, that is all gravy.

Another point: while coppice forests already support more biodiversity than unmanaged forests, we can do even better. Coppice forest management has progressed enormously over the years, and there are now a variety of techniques in practice that improve biodiversity still further, such as coppice-with-standards. But there is still room for further improvement.

Permaculture offers the opportunity to incorporate food production into coppice agroforestry, via techniques like growing edible species such as basswood, the co-production of pollard hay, the incorporation of various supporting species, and more.

Aside from coppice agroforestry, there are other carbon negative ways to fuel rocket mass heaters. One of the most promising is bamboo: a bamboo plantation sequesters a huge amount of carbon even when it is being selectively harvested. And like coppice agroforestry, it produces biomass that can be used in durable applications too, like construction.

When it comes to rocket mass heaters, bamboo even has an advantage over coppice wood: it burns very fast and hot. In a typical wood stove, that would be undesirable since continuous combustion is doing the heating. Since a rocket mass heater charges a thermal battery, the faster the charge, the better.

Bamboo is native to huge swaths of the planet, including large parts of the United States, and it can play a key role in creating a regenerative supply chain for heat. But just like trees, bamboo can be grown badly. Industrial bamboo plantations and the clearcutting of natural bamboo forests are not ecological positives. So a similar approach must be taken as with coppice agroforestry: manage for biodiversity, multiple uses, local production, and site improvement within the native ecosystem. That is what real efficiency looks like.

There are other options for rocket mass heater fuel, too: various waste materials, random twigs and branches, certain grasses, dried manure, basically anything that can burn. All of those can be part of the mix, too.

The Competition: Heat Pumps

Lastly, let’s compare all of this to the current faux silver bullet: heat pumps. In a heat pump, electricity is used to move a refrigerant called R-410A—which has 2,088 times more global warming potential than CO2—through a compressor, allowing it to exchange heat with either the outside air (less efficiently) or the ground (more efficiently). This process requires an enormous amount of electricity: enough to power 9 full-size refrigerators year round, on average.

A heat pump is a complex mechanical device made of plastic, copper, aluminum, steel, and various other synthetic materials, all of which have to be mined, refined, transported, melted, cast, milled, and disposed of. Suffice to say, this is an energy and material intensive industrial process that is ecologically harmful every step of the way.

Another consequence of this is that the average person cannot make a heat pump, nor can they install it, nor can they service it when it breaks down. That means that relying on heat pumps puts our lives at the mercy of long, complex, increasingly fragile supply chains and specialized labor. To top it all off, they have an average lifespan of only 15 years.

Contrast this with a rocket mass heater, which anyone can build and rebuild and even improve, using readily available materials. It has no moving parts, requires no electricity (and thus no transmission lines, power plants, copper mining, etc), and is entirely non-toxic. And all the fuel to heat a well-insulated house can be grown on as little as 1/10th of an acre. That’s a resilient, ecologically sound source of heat.

None of this is to say that rocket mass heaters alone can do the job. Any solution to a widespread need requires diverse, local solutions. There’s still plenty of room for solar air heaters, Jean Pain systems, passive solar design, and much much more.